Why Layer Farming is Your Next Smart Move

Looking to crack into Kenya’s agricultural gold mine? Layer chicken farming isn’t just another agricultural venture—it’s a consistent cash flow generator that’s transforming ordinary Kenyans into successful agripreneurs. With Kenya’s egg consumption hitting a massive 3.5 billion eggs annually and growing, you’re looking at a market that’s hungry for more.

Unlike seasonal crops that leave you waiting months for returns, layer farming delivers daily income through egg production. Whether you’re eyeing a side hustle or planning to scale into a commercial operation, the egg business offers something rare in agriculture: predictable, steady returns.

This guide cuts through the noise to give you everything you need to know about starting and running a profitable layer chicken farm in Kenya. From selecting the perfect breed to navigating market challenges, consider this your cheat code to poultry success.

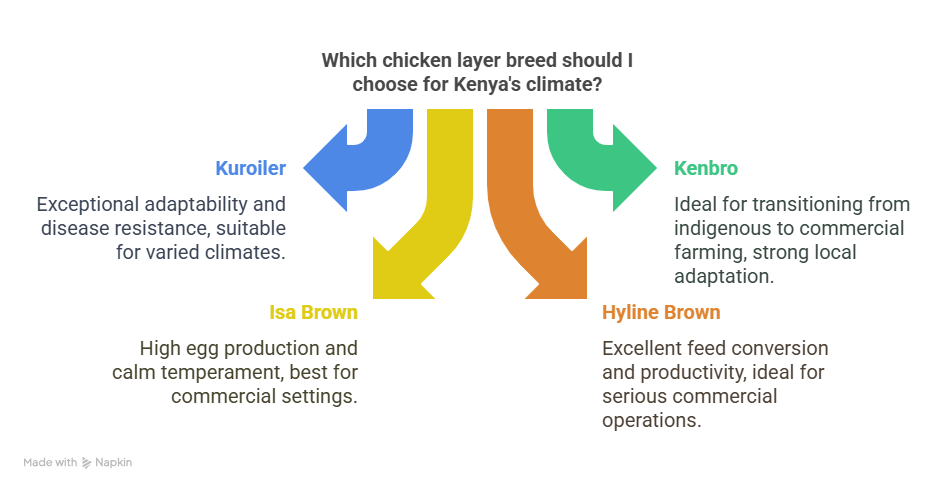

Choosing Your Champion: Top Layer Breeds for Kenya’s Climate

When it comes to layer breeds in Kenya, not all chickens are created equal. Your breed selection can make or break your profit margins. Here are the top performers that thrive in Kenya’s diverse climates:

Kuroiler: The Adaptability King

Kuroilers are hybrid powerhouses created by crossing Rhode Island Red and Kadaknath breeds. What makes them stand out? Their exceptional adaptability to Kenya’s varied climate zones and impressive disease resistance. These birds will reward you with 280-320 eggs annually when properly managed.

Their adaptability means less stress about regional climate variations—whether you’re farming in hot Mombasa or cooler Nakuru, Kuroilers can handle it.

Kenbro: The Local Hero

If you’re transitioning from indigenous chickens, Kenbros offer the perfect middle ground. They’re a cross between Kenyan Indigenous chickens and Rhode Island Reds, giving you birds that are pre-programmed to thrive in local conditions.

With an annual production of 280-300 eggs and strong disease resistance, Kenbros represent smart economics for farmers looking to upgrade from traditional to commercial systems without a steep learning curve.

Isa Brown: The Production Powerhouse

Isa Browns have earned their reputation as egg-laying machines. These hybrids of Rhode Island Red and White varieties consistently deliver 280-320 eggs yearly. Their calm temperament makes them ideal for commercial settings where efficiency is key.

If maximum production is your goal, Isa Browns deliver the goods without demanding advanced management skills.

Hyline Brown: The Commercial Favorite

For serious commercial operations, Hyline Browns are worth the investment. Created by crossing Rhode Island Red and Rhode Island White breeds, they’re productivity champions capable of producing 280-320 eggs annually under optimal conditions.

Their feed conversion efficiency makes them particularly attractive when you’re calculating cost per egg produced.

Rainbow Rooster: The Beginner’s Best Friend

These birds—a cross between Rhode Island Red, Plymouth Rock, and New Hampshire breeds—lay approximately 280-320 eggs annually. What sets them apart is their manageable temperament, making them perfect if you’re just starting your layer farming journey.

Their ease of management means fewer headaches as you learn the ropes of commercial egg production.

Housing: Building Your Layers’ Productivity Palace

Your housing system directly impacts egg production, bird health, and your operation’s profitability. Here’s how to get it right:

Housing Design Essentials

Your layer house needs to tick several boxes:

- Protection from predators and harsh weather

- Proper ventilation to regulate temperature and humidity

- Easy access for egg collection and cleaning

- Sufficient space to prevent stress and disease transmission

Successful farmers like Kasendi Mutinda from Kitui County demonstrate that well-designed housing with cemented structures and excellent ventilation creates the optimal environment for consistent egg production.

Cage Systems vs. Deep Litter: Making the Right Choice

Your two main housing options are:

Cage Systems: Individual or battery cages housing specific numbers of birds, each equipped with feeding troughs and watering systems. Mutinda’s successful operation demonstrates an effective setup where a single cage accommodates approximately 130 birds. These cages feature wire mesh bottoms that simplify egg collection and waste management.

Deep Litter Systems: More traditional setups where birds are housed on floors covered with absorbent materials like wood shavings or rice husks. This system requires more space but can be less expensive to set up initially.

For beginners, a small-scale deep litter system offers an accessible entry point. As you scale, transitioning to a cage system increases efficiency and production density.

Space Requirements: Giving Your Layers Room to Thrive

Don’t cut corners on space—overcrowding leads to stressed birds, reduced egg production, and increased disease risk. For optimal production:

- Caged layers: Minimum 450 square centimeters per bird

- Deep litter systems: 7-8 birds per square meter

Remember: cramped chickens lay fewer eggs, negating any space savings you might have hoped for.

Nutrition: Fueling Your Egg Factory

Feed accounts for 70-80% of your production costs, making nutrition management critical to profitability. Here’s how to get it right:

Feed Formulation by Production Stage

Your layers’ nutritional needs evolve throughout their lifecycle:

| Production Stage | Age | Protein Requirement | Key Nutrients | Purpose |

|---|---|---|---|---|

| Starter Feed | 0-8 weeks | 20-22% | Higher protein, vitamins | Support rapid growth and development |

| Grower Feed | 8-18 weeks | 16-18% | Balanced nutrition, prep for laying | Build body reserves without excess fat |

| Layer Feed | 18+ weeks | 16-18% | Higher calcium (3.5-4%), phosphorus | Support egg production and shell formation |

Getting the calcium balance right is essential for proper eggshell formation—deficiencies result in thin-shelled eggs prone to breakage, directly impacting your profits.

Feed Management Hacks to Cut Costs

With feed representing your biggest expense, these strategies can improve your bottom line:

- Custom feed formulation: Mixing your own feeds using locally available ingredients can reduce costs by 20-30% compared to commercial feeds

- Bulk purchasing: Negotiate better prices by buying feed ingredients in larger quantities

- Reduce wastage: Implement feeding troughs that prevent birds from scratching out feed

- Strategic feeding times: Feed during cooler hours when birds eat more efficiently

Water Supply: The Overlooked Production Booster

While everyone focuses on feed, water access significantly impacts egg production. Layers need constant access to clean, fresh water—they’ll stop laying long before they stop eating if water is restricted.

Smart farmers like Mutinda implement efficient systems with red-colored water drinkers positioned at regular intervals, capitalizing on chickens’ natural tendency to peck at red objects. This simple but science-backed approach ensures birds remain properly hydrated.

Lighting Programs: Illuminating Your Way to Higher Production

Light exposure directly influences egg production—it’s not just a convenience factor but a production tool. Here’s how to leverage light for maximum returns:

The Science Behind Lighting and Egg Production

A chicken’s reproductive system responds to light exposure. In commercial settings, extending daylight hours through artificial lighting can increase egg production by 20-30%.

For enclosed housing systems, implement a lighting program that gradually increases day length until reaching 16-17 hours, which triggers maximum egg production. The golden rule: never decrease day length during the laying period—it dramatically impacts productivity.

Practical Lighting Implementation

For small-scale farmers, simple solutions work:

- Use energy-efficient LED bulbs to reduce electricity costs

- Install timers to automate lighting schedules

- Ensure uniform light distribution throughout the house

- Maintain light intensity of 10-15 lux at bird level

Health Management: Protecting Your Investment

Disease outbreaks can wipe out your entire operation overnight. A comprehensive health management approach includes:

Vaccination Schedule That Works

Implement a strict vaccination program against common diseases like:

- Newcastle disease

- Infectious bronchitis

- Gumboro disease

- Fowl typhoid

- Fowl pox

Work with veterinary professionals to develop a customized vaccination schedule based on regional disease prevalence.

Biosecurity Measures That Don’t Break the Bank

You don’t need fancy equipment for effective biosecurity. Simple measures like footbaths at the house entrance prevent bacteria and pathogen transmission. Additional cost-effective measures include:

- Restricting visitor access to production areas

- Implementing regular cleaning protocols

- Proper disposal of dead birds and waste

- Quarantine procedures for new stock

- Pest and wild bird control

Production Cycle Economics: Understanding Your Cash Flow

Layer farming operates on a predictable cycle that determines your cash flow and management decisions:

Timeline From Chick to Peak Production

The journey from day-old chick to productive layer follows this timeline:

- Week 0-8: Brooding and early growth phase

- Week 8-18: Grower phase, building body reserves

- Week 18-22: Point of lay begins, production gradually increases

- Week 22-35: Production rises to peak (90-95% lay rate)

- Week 35-72: Gradual production decline

- Week 72-78: End of economic laying cycle

It takes 23-27 hours for an egg to form completely, meaning your hens won’t quite manage one egg per day, but close to it during peak production.

Real Numbers: What Profitability Looks Like

Let’s talk money. Mutinda’s operation with approximately 500 layers generates about 12 crates of eggs daily that sell for Ksh 280 per crate, translating to approximately Ksh 3,300 in daily revenue from egg sales alone.

With feed representing 70-80% of production expenses, your other significant costs include:

- Initial pullet acquisition

- Housing construction/maintenance

- Vaccinations and health management

- Labor

- Utilities (especially electricity for lighting)

The advantage of layer farming is that it generates daily income, unlike most agricultural ventures that force you to wait for harvest season.

Challenges and Smart Solutions

Even with its profit potential, layer farming in Kenya comes with challenges. Here’s how successful farmers navigate them:

Tackling Feed Cost Challenges

The rising cost of commercial feeds threatens profitability, especially in dry regions like Kitui County where Mutinda operates. Smart farmers address this by:

- Formulating their own feeds using locally available ingredients

- Buying feed ingredients in bulk during harvest seasons when prices are lower

- Incorporating alternative protein sources where appropriate

- Implementing efficient feeding systems that minimize waste

Winning at the Market Game

While Kenya has strong demand for eggs, market access challenges and price fluctuations affect profitability. Successful farmers like Mutinda establish reliable market channels in their local areas.

You can strengthen your market position by:

- Forming marketing cooperatives to increase bargaining power

- Developing direct relationships with hotels, restaurants, and institutions

- Adding value through proper grading, packaging, and branding

- Diversifying market channels rather than depending on a single buyer

Starting Your Layer Farming Journey: First Steps

Ready to dive into layer farming? Here’s how to begin:

- Start small, think big: Begin with 50-100 birds to develop management skills before scaling

- Location matters: Choose a site with good access to markets and inputs

- Knowledge is power: Connect with extension officers and successful farmers in your area

- Secure markets first: Establish where you’ll sell your eggs before your first flock reaches point of lay

- Record-keeping: Implement simple but comprehensive record systems from day one

Your Next Move in Layer Farming

Layer chicken farming in Kenya represents a golden opportunity to build a sustainable agribusiness. With annual egg consumption at 3.5 billion and growing, market demand remains robust, creating space for both new entrants and expanding operations.

Success stories like Mutinda’s demonstrate that with proper management practices, appropriate infrastructure, and attention to health and nutrition, layer farming provides reliable income even in challenging environments.

As Kenya’s population and urbanization continue to grow, egg demand is projected to increase further, supporting long-term industry viability. The question isn’t whether to get into layer farming—it’s how quickly you can start your journey toward daily egg profits.

Ready to take the next step? Connect with local agricultural extension offices or successful layer farmers in your area to learn more about breed availability and regional best practices.

What’s your biggest question about starting a layer chicken farm in Kenya? Drop it in the comments below, and let’s keep the conversation going!